Specialist Advice on Commercial Refrigeration Repair for Toronto Businesses

Wiki Article

Repairing Industrial Refrigeration Fixing: Techniques for Quick and Effective Fixes

In the realm of industrial refrigeration, the requirement for swift and exact troubleshooting strategies is extremely important. When a refrigeration system breakdowns, the effects can be disruptive and expensive to business procedures. Recognizing the usual issues that plague industrial refrigeration systems and having a toolkit of diagnostic methods available can make all the difference in promptly determining and remedying issues. As we browse through the complexities of repairing business refrigeration fixing, we will reveal the crucial approaches for solving issues effectively, making certain that businesses can maintain optimum air conditioning efficiency and minimize downtime.Usual Business Refrigeration Issues

Business refrigeration systems typically run into a range of operational concerns that can disrupt their efficiency and efficiency. One common concern is improper temperature control, which can lead to food putridity and waste if not immediately dealt with.In addition, refrigerant leakages posture a significant worry as they not just affect the air conditioning capability of the system however likewise add to environmental damage. Detecting and repairing leaks promptly is essential to avoid additional damages and guarantee compliance with policies. In addition, filthy condenser coils can hinder warmth transfer, compeling the system to function more challenging and take in even more energy. Regular cleansing and maintenance can help prevent this issue and prolong the life-span of the refrigeration system.

Analysis Devices and Strategies

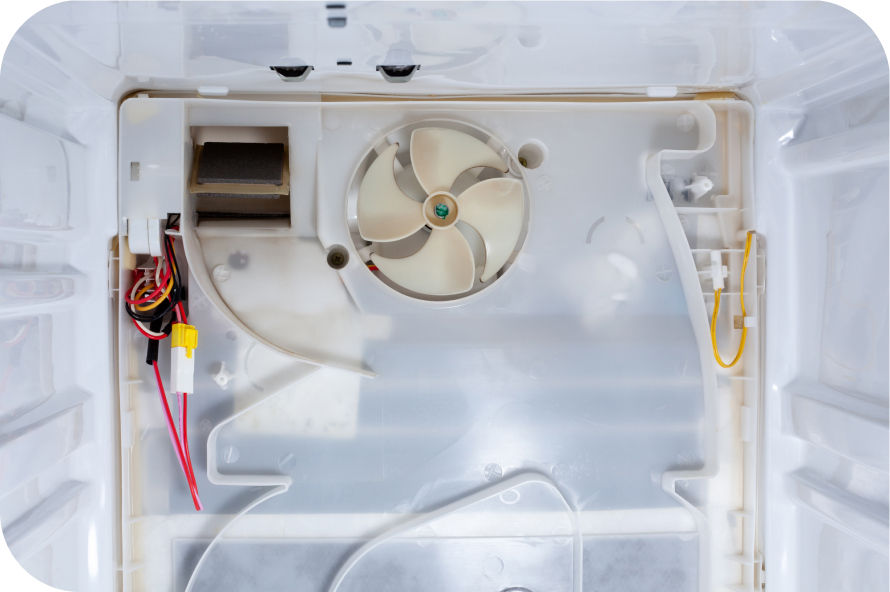

Effective troubleshooting of industrial refrigeration systems relies heavily on making use of specialized diagnostic tools and methods to identify and fix underlying issues efficiently. One important analysis device is the multimeter, which helps professionals gauge voltage, existing, and resistance in various components such as compressors, motors, and defrost heaters. Thermometers are likewise critical for examining temperature differentials throughout the system to determine prospective issues like refrigerant leakages or improper air movement. In addition, leakage discovery devices like digital leakage detectors or ultraviolet dye sets are vital for finding cooling agent leaks that can cause system inefficiencies.If the system has the proper cooling agent fee and determine any kind of leakages,Methods such as stress screening using manifold assesses can figure out. Aesthetic inspections of parts for signs of ice, wear, or corrosion buildup are likewise essential in identifying problems. Information loggers can be employed to keep an eye on system efficiency over time and spot trends that might indicate recurring troubles. By incorporating these diagnostic tools and strategies, service technicians can successfully repair industrial refrigeration systems and provide quick and exact repair work, reducing downtime and making sure optimal system efficiency.

Quick Repairs for Refrigeration Issues

When encountered with refrigeration problems, specialists can execute quick solutions to attend to common concerns swiftly and effectively. If the refrigeration system is not cooling down properly, checking and readjusting the thermostat setups might offer a fast remedy prior to even more in-depth troubleshooting is called for. By executing these quick fixes, specialists can attend to common refrigeration troubles effectively and maintain industrial refrigeration systems running efficiently.

Preventative Maintenance Tips

Implementing a positive upkeep routine is important for guaranteeing the long life and ideal efficiency of commercial refrigeration systems. Routine upkeep not just assists stop expensive breakdowns yet also makes certain that the devices operates effectively, saving power and lowering total operating expense. Below are some preventative maintenance suggestions to keep industrial refrigeration systems running smoothly:

Examine and Replace Filters: Filthy filters can limit air flow, making the system work tougher and potentially causing damage. Inspect and replace filters routinely to prevent concerns.

Inspect Seals and Gaskets: Leaky seals and gaskets can result in temperature level changes and energy waste. Inspecting and replacing damaged seals can assist keep regular temperature levels.

Expert Assistance and Services

To preserve the optimal performance achieved with regular preventative maintenance, seeking specialist assistance and solutions for business refrigeration systems is necessary. Expert service technicians have the competence and specialized knowledge required to identify and address intricate problems successfully. When dealing with difficult refrigeration troubles, counting on expert assistance can conserve both time and money in the future.Expert solutions supply advantages such as accessibility to advanced tools and devices, ensuring that fixings are lugged out effectively. Furthermore, service technicians are trained commercial refrigeration repair to abide by market policies and security requirements, minimizing the danger of accidents and guaranteeing conformity with legal requirements.

Verdict

To conclude, troubleshooting business refrigeration repair service calls for a methodical approach to identifying usual concerns, making use of diagnostic tools and strategies, applying fast fixes, and focusing on preventative upkeep. Expert assistance and services might be necessary for even more complex troubles - Toronto commercial refrigerator repair. By adhering to these methods, services can ensure their refrigeration systems operate successfully and successfully, reducing downtime and possible lossesComprehending the typical problems that plague commercial refrigeration systems and having a toolkit of analysis strategies at your disposal can make all the distinction in swiftly recognizing and fixing troubles.Effective troubleshooting of industrial refrigeration systems counts heavily on making use of specialized analysis tools and strategies to recognize and deal with underlying problems effectively. By incorporating these analysis tools and techniques, service technicians can effectively troubleshoot industrial refrigeration systems and give precise and quick repair work, lessening downtime and making sure optimum system performance.

By executing these quick fixes, technicians can resolve usual refrigeration troubles effectively and keep business refrigeration systems running smoothly.

Additionally, professional assistance can help expand the life expectancy of commercial refrigeration systems by identifying prospective issues prior to they escalate.

Report this wiki page